- Monitor Basics in Plain English

- 10 ways to address eye fatigue caused by displays

- EIZO 4K Monitors – high definition and large screen sizes

- Confused about HiDPI and Retina display? ― Understanding pixel density in the age of 4K

- EIZO Optical Bonding

- The Latest on Computer Screens and Eye Fatigue

- Pixel Pitch and Enlarged Mode

- Native Resolution and Enlarge Mode

- How can a screen sense touch? A basic understanding of touch panels

- Is the beauty of a curve decisive for color reproduction? Learning about LCD monitor gamma

- Smoother Video with Cutting-Edge Technologies: LCD Monitor I/P Conversion

- Altering color dramatically with a single setting: Examining color temperature on an LCD monitor

- Maximum Display Colors and Look-Up Tables: Two Considerations When Choosing a Monitor

- DisplayPort to D-Sub: The Full Range of LCD Monitor Video Input Interfaces

- The Ability to Display Color Correctly Is Vital: Understanding the Color Gamut of an LCD Monitor

- The Making of a FlexScan Monitor

- Are the response time figures true? A close look at LCD video performance

- The difference in image quality is perfectly obvious! – Let's check the LCD's display

- Making Full Use of the "External" LCD with Laptop Computers

- Videos

- Color Management Resources

EIZO has an in-house production line for optical bonding - a method with which to provide increased visibility and durability to LCD monitors. Producing optical bonding in-house allows EIZO to continue to meet the needs of maritime, medical, and other specialty markets while ensuring each product maintains high quality standards.

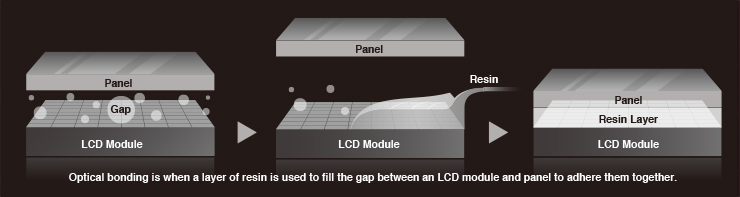

What is optical bonding?

There is a small gap of air that lies between the LCD module and the cover glass or touch panel of a monitor. Optical bonding is a process in which a layer of resin is used to fill the gap, adhering the two together.

Benefits of Optical Bonding

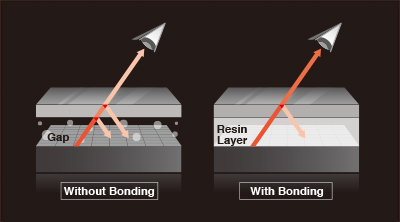

Clear Display

Images shown on a monitor are reflections generated by light from the LCD module passing through the gap and the panel. The gap and panel have different refractive indexes, causing the light to bend when it passes through them. This results in a loss in its intensity, affecting the screen’s readability. Images shown on a monitor are reflections generated by light from the LCD module passing through the gap and the panel. The gap and panel have different refractive indexes, causing the light to bend when it passes through them. This results in a loss in its intensity, affecting the screen’s readability. |

By adhering the LCD module and panel together with optical bonding, the transmission of light is increased, improving the visibility of the display. This is useful when viewing a monitor with bright ambient lighting conditions.

|

|

|

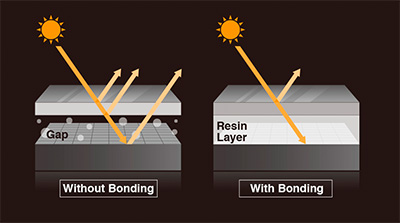

Glare Reduction

When light from an external source passes through the panel and the gap, refraction causes some of it to be reflected back, creating glare on the screen. The increased light transmission of a screen with optical bonding significantly reduces glare from external light sources. When light from an external source passes through the panel and the gap, refraction causes some of it to be reflected back, creating glare on the screen. The increased light transmission of a screen with optical bonding significantly reduces glare from external light sources. |

The reduced glare that optical bonding provides makes it an ideal option when viewing a monitor outdoors or in environments with an intense direct light source.

|

|

|

Increased Physical Durability

|

|

This provides high durability for use in public access areas, factories, or other environments where the monitor is routinely used.

|

|

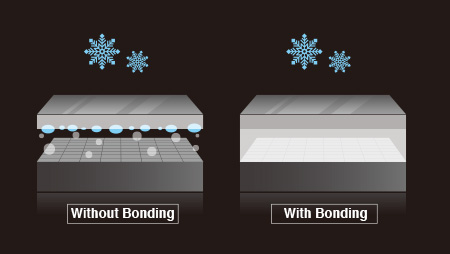

No Condensation

|

|

This makes optical bonding ideal for ships and offshore structures, warehouses, aircrafts, and other environments that experience extreme temperature changes.

|

|

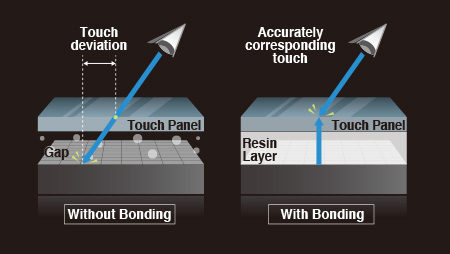

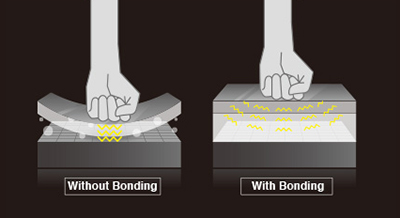

Accurate Touch Experience

For touch monitors, the panel thickness influences touch accuracy and can affect usability with both touch pens and bare hands. A touch monitor with optical bonding maintains consistently accurate touch response making it easy to use and reliable. For touch monitors, the panel thickness influences touch accuracy and can affect usability with both touch pens and bare hands. A touch monitor with optical bonding maintains consistently accurate touch response making it easy to use and reliable. |

The additional resin layer in optical bonding also provides increased physical durability to the screen. Eliminating the gap between the LCD module and the panel increases the screen’s resistance to scratches, dust, and fluids.

The additional resin layer in optical bonding also provides increased physical durability to the screen. Eliminating the gap between the LCD module and the panel increases the screen’s resistance to scratches, dust, and fluids. In environments with wide temperature ranges, it is common for condensation to cause screens to become foggy from moisture that penetrates the air gap. A monitor with optical bonding fills the gap to prevent condensation from occurring for improved readability.

In environments with wide temperature ranges, it is common for condensation to cause screens to become foggy from moisture that penetrates the air gap. A monitor with optical bonding fills the gap to prevent condensation from occurring for improved readability.